FAQ.

How does recycling with Fungi work?

We accept waste materials like untreated sawdust and media production backdrops from local businesses which are shredded, hydrated and sterilized. This clean material, called a substrate is introduced to a fungi culture which then grows through the material.

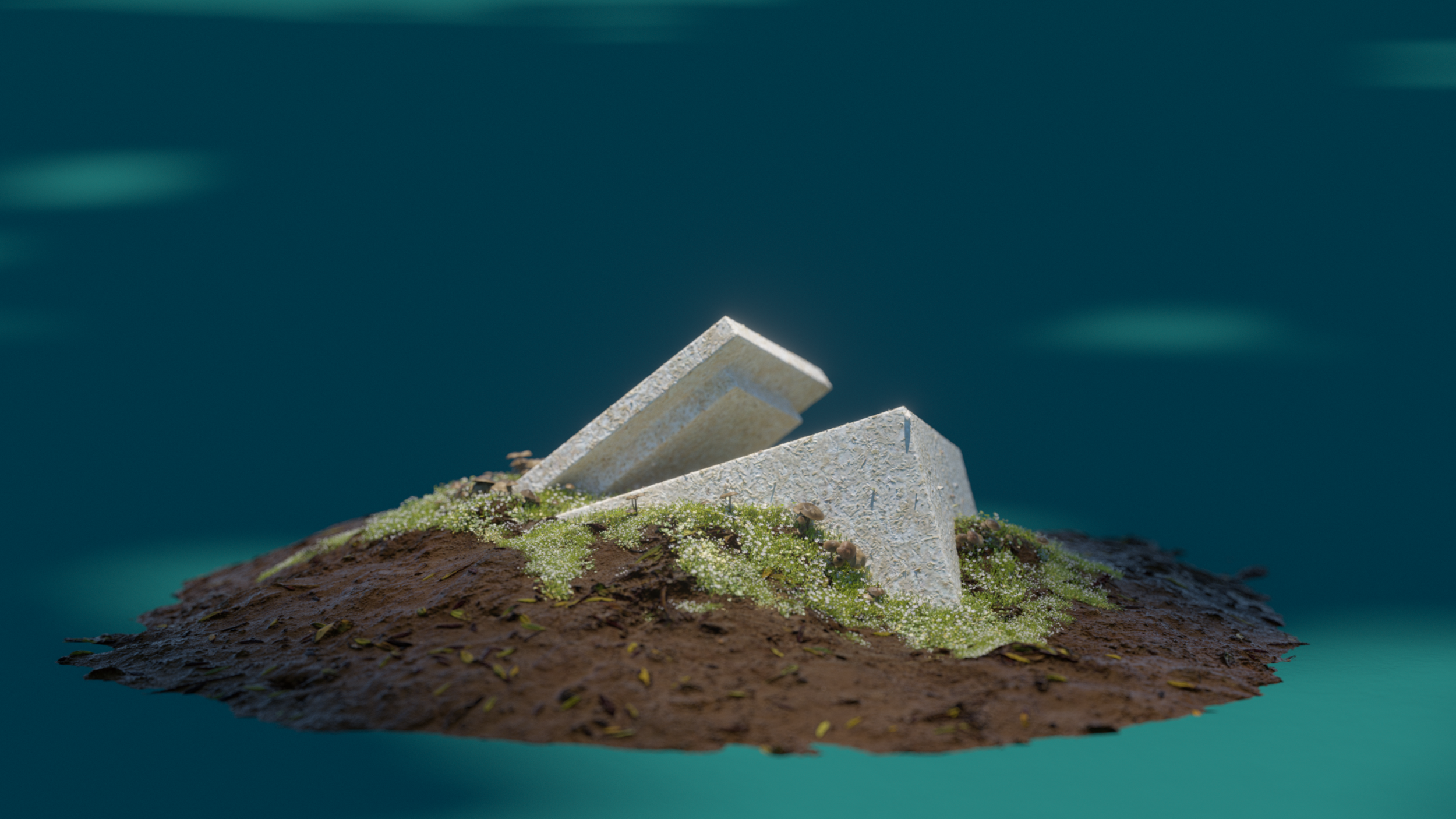

The root network of the fungi bonds together the waste substrate and moulds it into a new form. The structure is harvested and heat treated to create the resulting mycomaterial. Once heat-treated it can not regrow and will remain stable while dry. To dispose of the mycomaterial products, simply soak in water overnight and then add to compost.

This process captures resources that would otherwise be sent to landfill and creates a sustainable alternative to single use plastics and synthetic foams in the process.

What are mycomaterials?

Mycomaterials are made from the mycelium or the mushroom fruit body of a Fungi that is fused with a waste substrate. The substrate such as sawdust or hemp hurds provides nutrition for the fungi to develop a mycelium root network that bonds together the materials.

Once it has finished growing the mycelium is heat treated to create an inert biocomposite material that is lightweight, thermally and acoustically insulating and fire resistant.

How long does it take to grow?

Cultivation takes around one month start to finish.

Are mycomaterials safe?

Yes they are, mycomaterials are organic, inert and perform well against comparable synthetic materials. Below we have outlined areas of consideration;

Performance?

Materials made with mushrooms have been shown to outperform comparable synthetic materials and boast exceptional performance in fire safety and lifecycle analysis.

In comparison to synthetic materials on the market like the commonly available polyurethane foams used for auditory dampening in studios and office spaces, which are non renewable, energy intensive to produce (Bandyopadhay & Basak 2007) and degrade within 7 years, while releasing toxins into the air that creates a well-documented environmental and public health problem (Padula et al. 2014;Hofer 2008). Mycelium on the other hand is a clean and organic solution to your insulation, packaging and product needs.

Fire Rating?

Mycelium has excellent fire retardant qualities. The production of char on the surface has been shown to reduce flame spread. Unlike synthetic materials, mycomaterials do not produce toxic smoke and pose a “lower fire safety hazard than synthetic XPS foams'' (Jones, Bhat et al. 2017.) This can improve fire safety and protect other equipment and materials in your spaces.

Biosecurity?

All of our Myco-Materials are heat treated to create a nonliving composite material that is not able to regrow and can be safely composted at the end of use. The treatment process ensures that there is no risk of spreading nonnative fungi and ensures that Australia’s natural biodiversity is protected.

What to do with the materials after use?

Our mycelium materials can be kept indefinitely in dry conditions and reused in your home. If you would like to recycle your Myco-Materials soak in water overnight and then add to compost or your garden, aerate and mix well into the soil. The Myco-Materials will biodegrade over the next 6 weeks and provide nutrition to your garden biome and promote healthy soil ecosystems.